In the final weeks of school last June, students in Intro to Engineering Design in the STEM pathway worked on an exciting project to design and build a fastener that could securely attach a toy windmill to a model playhouse, simulating a real-world problem-solving experience. Students acted as engineers hired by a toy company to create an innovative and reliable solution. The scenario was fictional, but the skills being developed were very real.

The requirements were strict–the design had to be secure, easy to use, and cost-effective. Teams also had to consider how the windmill would function when attached, taking into account factors such as movement, durability, and safety. The project not only reinforced technical skills but also built communication and problem-solving abilities among students.

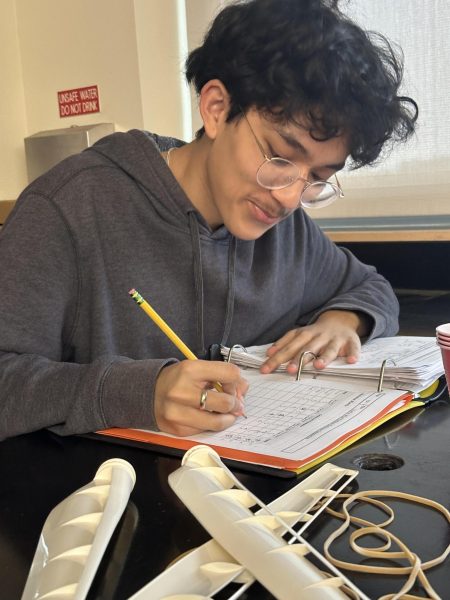

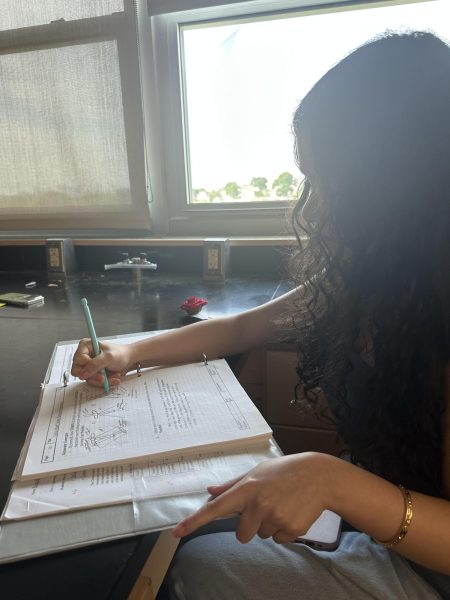

Throughout the process, students analyzed their results, identified design flaws, and improved their models based on performance and feedback, all along following the steps of the engineering design process.

“Each component of the engineering design process was touched upon in this project,” engineering teacher Michelina Tumblin explained. “The problem was identified and defined by students. Each student came up with multiple possible solutions, picked which one they believed to be the best, and used a decision matrix to compare their ideas with their teammates to numerically determine which idea would be most successful.”

“They planned their designs and developed them by creating technical drawings,” Tumblin continued. “They used provided materials to bring their ideas to reality, and went to the playground at Glendale Park to see if their build could work on any playhouse. After the fasteners were tested, the engineers reviewed the test and documented which aspects worked, which needed improvement, and how that could be done.”

Students said the project really made them feel like engineers.

“I learned how engineers work through problems,” sophomore Bridgit Elias Mendez said. “I applied the steps of the engineering design process. When we noticed something was wrong or something that could be better, we all worked together to find a way to fix and improve it.”

In addition, students had to use critical thinking, collaboration, and creativity skills. “One thing I enjoyed from this project was being able to work with my classmates to collaborate on ideas to find the best solution,” sophomore Kevin Rivas said.

“We did a lot of research on different materials before starting this project, which helped us brainstorm,” sophomore Krivi Maharjan added. “All of my team members had different ideas, so we used a decision matrix to choose. I liked the way our team collaborated and put in equal effort with brainstorming, building, and also working on the presentation.”

However, coming up with the projects and making sure the fastener design had to fit the criteria and constraints also came with problems.

“For the project, we also had to make a presentation to show the steps we took in our design process, which I didn’t enjoy,” sophomore Miguel Perez Rivera said. “I liked the hands-on building part more and being able to go outside to test our design and then also improve it later on.”

“Making this project felt like getting all the pieces to fit in a puzzle,” Maharjan said. “We had our fair share of problems with design brainstorming, but we got through it. This project showed me that teamwork and communication are key in these types of work areas and careers, especially engineering.”

Different teams of students took various approaches, including snap-on clips, twist-lock designs, rubber band inserts, and velcro parts, showing a wide range of solutions to the same core problem.

“Our group based our project on a claw system with three legs with multiple bending joints,” sophomore William Hurley said. “It was mainly made out of cardboard and supported by popsicle sticks. The joints were made out of straws and skewers. We wanted to make sure it was able to grapple and secure onto any surface.”

“From this project, I learned the importance of the versatility of the solution, like it should be able to work for different problems and situations based on the consumer,” Rivas said.

This project overall helped students understand how real engineers solve problems.

“I got to practice all the useful skills I have learned that year into a single project, which I enjoyed,” sophomore Sienna Kaplan said. “We learned somewhat how engineers think because of the criteria, teamwork, and brainstorming.”

“I think real-life engineers should make this into a real product because the environment is a big issue right now, and this would be a way to help effectively make energy around the community, even if it would only provide a little help to this major problem,” Maharjan said.

Overall, the project challenged students and helped them use their skills they had learned throughout the year into one final project.